EM-02: standard expanded metal

Expanded metal is a versatile and economical product that can meet various demands in different situations. The sheet, plate or coil be cut or slit and stretched into numbers of regular opening diamonds on the surface is called expanded metal.

Compared with its alternatives, expanded metal is more rigid and won't ravel if part is cut off because it is slit rather than perforated. And it is more cost-effective on account of its special expanding technic which causes none material loss in the manufacturing process. According to its different materials and wide ranges of specifications, expanded metal is used in different places. It is an ideal product used as fencing guard, partition, stair tread and catwalk grating. Therefore we provide a wide range of expanded products, as following:

EM-01: expanded metal sheet

By styles:

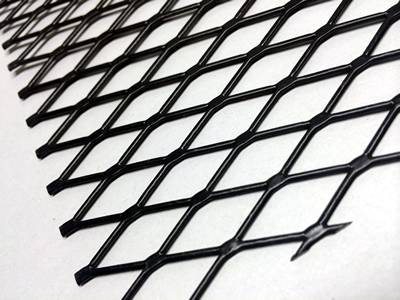

After slit and stretched, the sheet rises and falls regularly, which we called standard expanded metal (raised or regular expanded metal). After passing through the rolling mill the flattened expanded metal is finished.

EM-02: standard expanded metal

EM-03: flattened expanded metal

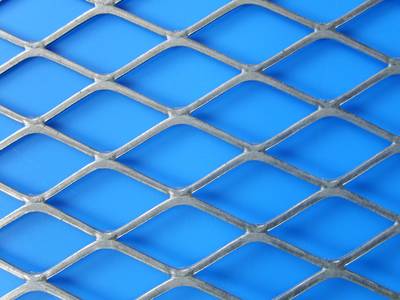

By materials:

Many kinds of metals and alloys are suitable for expanded metal: carbon steel, stainless steel, aluminum, copper and alloy of nickel are very common materials. Then stainless expanded metal with different chemical elements can also be divided into such several types: Types 304, 304L, 316, 316L. The specifications vary with different types slightly.

EM-04: carbon steel expanded metal

EM-05: stainless expanded metal

EM-06: aluminum expanded metal

EM-07: copper expanded metal

By finish types:

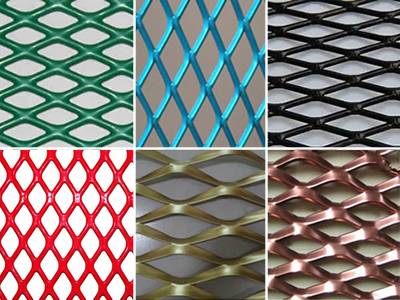

The usual finish methods include pre-galvanizing, hot-dip galvanizing, galfan-coating, anodizing, enameling, power coating, painting, PVC coating, etc. The most popular finish method for iron and steel products is galvanizing. Expanded metal can be sprayed or plated into any color. It is necessary for you to specify the wanted type of coating, thickness and color of finish.

EM-08: galvanized expanded metal

EM-09: green PVC coated expanded metal

EM-10: black power coated expanded metal

EM-11: different hole shapes and colors of expanded metal.

By hole shapes:

EM-12: expanded metal manufacturing process

The small animation shows that the top cutting die descends and simultaneously slits and cold forms an entire row of half diamonds; and then the top die ascends and moves one half diamond right as the base metal moves forward one strand width. With different shapes of cutting dies in machine, different shapes of openings are formed. diamond openings, hexagon openings, square openings, round openings and fan-shaped openings.

EM-13: expanded metal with diamond openings

EM-14: expanded metal with hexagon openings

EM-15: expanded metal with square openings

EM-16: expanded metal with diamond and hexagon openings

Edge configuration:

Condition of edge refers to two types: random (open) and bond (closed). Each sheet shall have closed diamond openings on all sides of the sheet unless ordered differently.

EM-17: Two end random shearing edges and two end bond shearing edges.

Manufacturing tolerances:

EM-18: LWD will not vary from the nominal dimension more than 1/4-in. per foot (2 mm per 100 mm) of dimension.

EM-19: The thickness of flattened expanded metal shall not be less than 80 % of the nominal thickness of the corresponding raised expanded metal thickness.

Features:

Application:

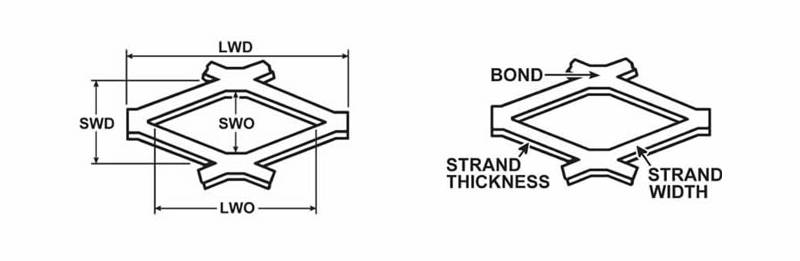

Terminology:

For your convenience, certain knowledge of expanded metal specification is necessary. Its worth mentioning, SWD always given before LWD when ordering.

EM-20:

SWD = short way of design

LWD = long way of design

SWO = short way of opening

LWO = long way of opening

bond = knuckle

EM-21: Standard flow expanded metal means LW parallels LWD of panel, reverse flow expanded metal means SW parallels LWD of panel.

NOTE: Span of expanded metal grating always parallels LWD.

| Style | Minimum thickness (Inches)A |

Nominal weight in Lbs. per 100 Sq. Ft.B |

Design Size (Inches)C |

Opening size (Inches) |

Strand size (Inches) |

Overall thickness (Inches) |

No. Of diamonds Per Ft. |

Open area (%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SWD | LWD | SWO | LWO | Width | Thickness | SWD | LWD | |||||

| 1⁄4"-#20 | .032 | 85 | .250 | 1.00 | .157 | .718 | .072 | .036 | .146 | 48 | 12 | 42 |

| 1⁄4"-#18 | .042 | 113 | .250 | 1.00 | .146 | .718 | .072 | .048 | .151 | 48 | 12 | 42 |

| 1⁄2"-#20 | .032 | 42 | .500 | 1.20 | .407 | .938 | .072 | .036 | .146 | 24 | 10 | 71 |

| 1⁄2"-#18 | .042 | 69 | .500 | 1.20 | .382 | .938 | .088 | .048 | .180 | 24 | 10 | 65 |

| 1⁄2"-#16 | .053 | 85 | .500 | 1.20 | .372 | .938 | .087 | .060 | .183 | 24 | 10 | 65 |

| 1⁄2"-#13 | .083 | 141 | .500 | 1.20 | .337 | .938 | .096 | .090 | .212 | 24 | 10 | 62 |

| 3/4"-#16 | .053 | 54 | .923 | 2.00 | .783 | 1.750 | .101 | .060 | .208 | 13 | 6 | 78 |

| 3⁄4"-#13 | .083 | 77 | .923 | 2.00 | .760 | 1.688 | .096 | .090 | .212 | 13 | 6 | 79 |

| 3⁄4"-#10 | .083 | 117 | .923 | 2.00 | .718 | 1.625 | .144 | .092 | .300 | 13 | 6 | 69 |

| 3⁄4"-# 9 | .127 | 178 | .923 | 2.00 | .675 | 1.562 | .150 | .134 | .329 | 13 | 6 | 67 |

| 1"-#16 | .053 | 43 | 1.00 | 2.40 | .872 | 2.062 | .087 | .060 | .183 | 12 | 5 | 83 |

| 1 1⁄2"-#18 | .042 | 20 | 1.33 | 3.00 | 1.229 | 2.625 | .068 | .048 | .144 | 9 | 4 | 90 |

| 1 1⁄2"-#16 | .053 | 40 | 1.33 | 3.00 | 1.184 | 2.625 | .108 | .060 | .221 | 9 | 4 | 84 |

| 1 1⁄2"-#13 | .083 | 58 | 1.33 | 3.00 | 1.160 | 2.500 | .105 | .090 | .228 | 9 | 4 | 84 |

| 1 1⁄2"-#10 | .083 | 76 | 1.33 | 3.00 | 1.132 | 2.500 | .138 | .090 | .288 | 9 | 4 | 79 |

| 1 1⁄2"-# 9 | .127 | 119 | 1.33 | 3.00 | 1.087 | 2.375 | .144 | .134 | .318 | 9 | 4 | 78 |

| 1 1⁄2"-# 6 | .184 | 247 | 1.33 | 3.00 | .979 | 2.313 | .203 | .198 | 452 | 9 | 4 | 69 |

| 2"-#10 | .083 | 65 | 1.85 | 4.00 | 1.630 | 3.438 | .164 | .090 | .335 | 6.5 | 3 | 82 |

| 2"-# 9 | .127 | 88 | 1.85 | 4.00 | 1.603 | 3.375 | .149 | .134 | .327 | 6.5 | 3 | 84 |

|

A The minimum thickness is absolute, not subject to minus variation. |

||||||||||||

| Style | Minimum thickness (Inches)A |

Nominal weight in Lbs. per 100 Sq. Ft.B |

Design Size (Inches)C |

Opening size (Inches) |

Strand size (Inches) |

Overall thickness (Inches) |

No. Of diamonds Per Ft. |

Open area (%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SWD | LWD | SWO | LWO | Width | Thickness | SWD | LWD | |||||

| 1⁄4"-#20 | .026 | 74 | .250 | 1.05 | .092 | .715 | .079 | .029 | .029 | 48 | 11.6 | 37 |

| 1⁄4"-#18 | .034 | 100 | .250 | 1.05 | .090 | .715 | .080 | .038 | .038 | 48 | 11.6 | 36 |

| 1⁄2"-#20 | .026 | 37 | .500 | 1.26 | .342 | 1.000 | .079 | 029 | .029 | 24 | 9.5 | 68 |

| 1⁄2"-#18 | .034 | 61 | .500 | 1.26 | .306 | 1.000 | .097 | .038 | .038 | 24 | 9.6 | 61 |

| 1⁄2"-#16 | .043 | 77 | .500 | 1.26 | .304 | 1.000 | .098 | .048 | .048 | 24 | 9.5 | 61 |

| 1⁄2"-#13 | .066 | 126 | .500 | 1.26 | .286 | 1.000 | .107 | .072 | .072 | 24 | 9.5 | 57 |

| 3/4"-#16 | .043 | 47 | .923 | 2.10 | .701 | 1.750 | .111 | .048 | .048 | 13 | 5.7 | 76 |

| 3⁄4"-#14 | .054 | 56 | .923 | 2.10 | .713 | 1.760 | .105 | .060 | .060 | 13 | 5.7 | 77 |

| 3⁄4"-#13 | .066 | 67 | .923 | 2.10 | .711 | 1.781 | .106 | .072 | .072 | 13 | 5.7 | 77 |

| 3⁄4"-#10 | .066 | 102 | .923 | 2.10 | .603 | 1.755 | .160 | .072 | .072 | 13 | 5.7 | 65 |

| 3⁄4"-#9 | .101 | 157 | .923 | 2.10 | .593 | 1.688 | .165 | .108 | .108 | 13 | 5.7 | 64 |

| 1"-#16 | .043 | 38 | 1.000 | 2.52 | .804 | 2.250 | .098 | .048 | .048 | 12 | 4.684 | 80 |

| 1 1⁄2"-#16 | .043 | 35 | 1.330 | 3.15 | 1.092 | 2.750 | .119 | .048 | .048 | 9 | 3.75 | 82 |

| 1 1⁄2"-#14 | .054 | 43 | 1.330 | 3.15 | 1.098 | 2.750 | .116 | .060 | .060 | 9 | 3.75 | 83 |

| 1 1⁄2"-#13 | .066 | 51 | 1.330 | 3.15 | 1.098 | 2.750 | .116 | .072 | .072 | 9 | 3.76 | 83 |

| 1 1⁄2"-# 9 | .101 | 105 | 1.330 | 3.15 | 1.014 | 2.563 | .158 | .108 | .108 | 9 | 3.75 | 76 |

|

A The minimum thickness is absolute, not subject to minus variation. |

||||||||||||

Item No.:

Item No. Is especially vital for the sake of ordering. For example:

Item No. : 1/2" #18F 4' SWD × 8' LWD

NOTE: F represents flattened, R represents raised.

Customization:

Standard specifications can be found in every specific product pages. And as an experienced manufacturer, special expanded metal with different materials, opening shapes and sizes, coatings, are available for clients' various demands.

Accessories:

The expanded metal is usually used as fencing guards, walkways, stair treads and decorates, and the requisite accessories for clients' demands, such as posts, rails, tension bars, tie wires clips for fencing, is all fitted as you can see in every specific product pages, but extra-chargeable.

Installation method:

The installation method for expanded metal is the same as any other metal sheet product for building.

Packaging and transportation:

To protect the goods, expanded metal is packed in sheet or roll into carton, crate or pallet and so on. International transportation procedures vary with the type of goods, delivery time and destination, but to meet your requirement our service specialists are always available for your request.

Discount: Discount varies with the type and quantity.

Ordering procedures: To improve users experience, please indicate the following data: material type, flattened or standard, wire diameter, hole shape, SWD, LWD, SWO, LWO, LW, SW, strand thickness (gauge), strand width, finish type, the thickness of coating, edge condition, weight per square ft. Accessories, packing and transportation method, etc. Therefore item No. is especially vital for ordering.

how can we help you?

Contact Anping Enzar Metal Products Co., Ltd. or submit a problem.